This is something new to me. I was aware that traditional electrolytic capacitors tend to fail as their wet electrolyte dries out, and while they keep the same capacitance value their ESR (Equivalent Series Resistance) rises causing ripple and timing issues. However, I’ve always just thought that metallised film capacitors either worked or didn’t. But now I know better.

Y’see, the capacitors are made of two layers of metallised plastic film wound together in a roll, creating alternate layers of insulator and conductor. There’s no wet electrolyte, so they can’t really dry out as such. But they have an intriguing characteristic sometimes referred to as “self-healing” whereby if a voltage spike exceeds the insulating capability of the insulating (dielectric) film then a tiny spark can arc through, but because the metallisation layer is very thin it tends to just vaporise and clear the fault. But what I’ve discovered here is that over time the metal film can get eroded away to the point that the conductive area is reduced dramatically with a matching reduction in the capacitance value.

Fortunately this is easily detected simply by measuring the capacitor with a capacitance meter.

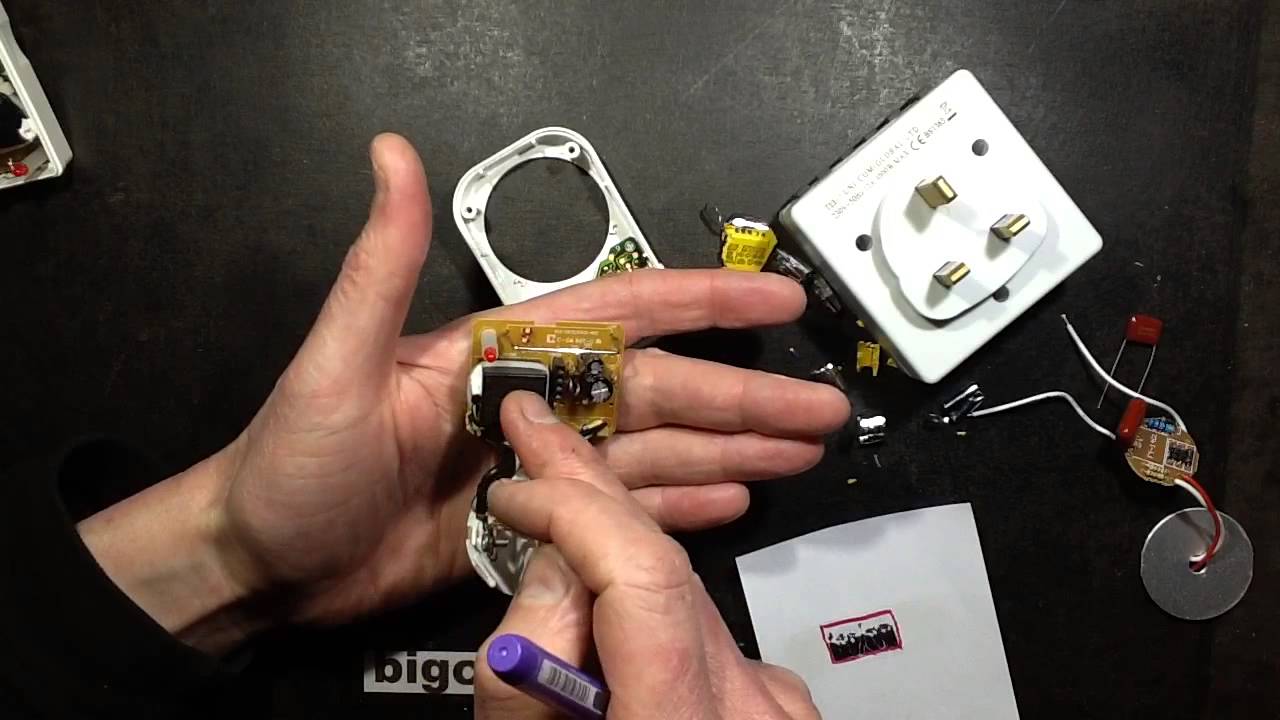

So in devices that use a capacitive dropper to derive a power supply, the steady degradation will ultimately reduce the current it passes and cause voltage issues as current is drawn by the circuitry. In both the time switch and remote switch featured in the video it was the current requirement of the relay that made the issue visible as it either failed to pull in at all or pulled in, but then dropped out again as the voltage fell on the smoothing capacitor.

Suddenly the failure of dimmer and remote wall switches all makes sense now. I really didn’t suspect the capacitor as being a likely candidate as I thought it would either work or just fail outright.

This could also cause issues with interference suppression networks where the gradual failure of the foil reduces the suppression capacitors ability to shunt or absorb transients, and could lead to problems with interference crashing processors.

The snubber networks across triacs could fail making them susceptible to inductive loads causing the triac to false trigger erratically.

In the case of the capacitive power supplies in many LED lamps with the suspiciously small capacitors suggesting thinner and thinner insulation it could lead to progressive loss of lamp intensity over time simply down to the capacitor not letting as much current pass on each half cycle of the mains waveform.

And the fix? If in doubt just change the capacitor for a new one.