more at

“HYDRAULIC BRAKES: PRINCIPLES OF OPERATION, PART 1 (DRUM BRAKES)”

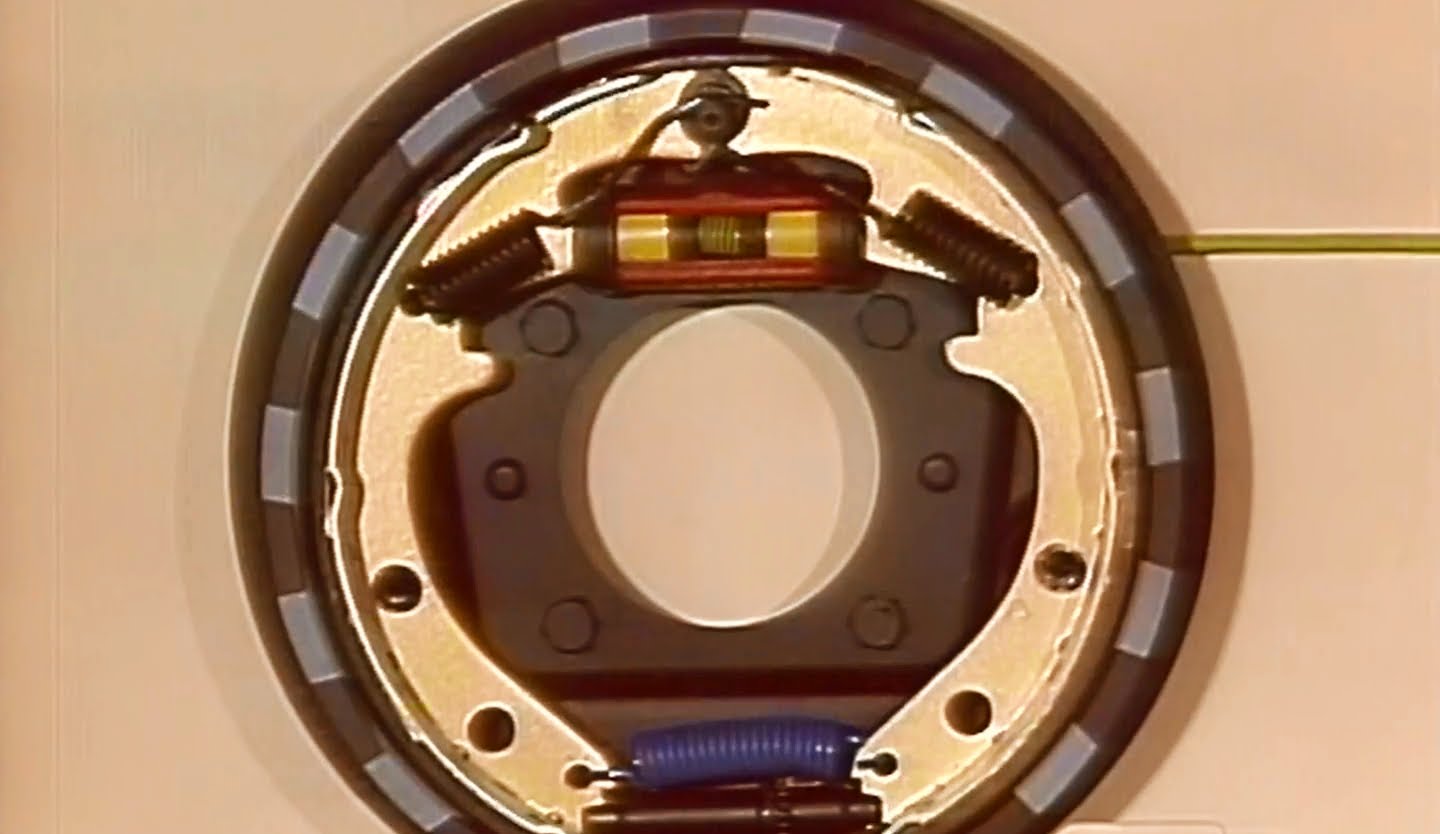

“THIS PROGRAM DEMONSTRATES THE BASIC PRINCIPLES OF HYDRAULIC BRAKE SYSTEM OPERATION. USING THE M151 WHEELED VEHICLE DRUM BRAKE SYSTEM, THE FOLLOWING MAJOR COMPONENTS ARE IDENTIFIED AND SHOWN IN OPERATION: MASTER BRAKE CYLINDER, WHEEL CYLINDERS, BRAKE SHOES AND ASSEMBLY AND BRAKE DRUM.”

US Army training film TVT 9-66

Reupload of a previously uploaded film with more improved video & sound.

Public domain film from the US National Archives, slightly cropped to remove uneven edges, with the aspect ratio corrected, and one-pass brightness-contrast-color correction & mild video noise reduction applied.

The soundtrack was also processed with volume normalization, noise reduction, clipping reduction, and/or equalization (the resulting sound, though not perfect, is far less noisy than the original).

see also:

Auto Mechanics playlist:

A drum brake is a brake in which the friction is caused by a set of shoes or pads that press against a rotating drum-shaped part called a brake drum.

The term “drum brake” usually means a brake in which shoes press on the inner surface of the drum. When shoes press on the outside of the drum, it is usually called a clasp brake. Where the drum is pinched between two shoes, similar to a conventional disk brake, it is sometimes called a “pinch drum brake”, although such brakes are relatively rare. A related type of brake uses a flexible belt or “band” wrapping around the outside of a drum, called a band brake.

The modern automobile drum brake was invented in 1902 by Louis Renault, though a less-sophisticated drum brake had been used by Maybach a year earlier. In the first drum brakes, the shoes were mechanically operated with levers and rods or cables. From the mid-1930s the shoes were operated with oil pressure in a small wheel cylinder and pistons (as in the picture), though some vehicles continued with purely-mechanical systems for decades. Some designs have two wheel cylinders.

The shoes in drum brakes are subject to wear and the brakes needed to be adjusted regularly until the introduction of self-adjusting drum brakes in the 1950s. In the 1960s and 1970s brake drums on the front wheels of cars were gradually replaced with disc brakes and now practically all cars use disc brakes on the front wheels, with many offering disc brakes on all wheels. However, drum brakes are still often used for handbrakes as it has proven very difficult to design a disc brake suitable for holding a car when it is not in use. Moreover, it is very easy to fit a drum handbrake inside a disc brake so that one unit serves as both service brake and handbrake.

Early type brake shoes contained asbestos. When working on brake systems of older cars, care must be taken not to inhale any dust present in the brake assembly…

In operation

Normal braking

When the brakes are applied, brake fluid is forced under pressure from the master cylinder into the wheel cylinder, which in turn pushes the brake shoes into contact with the machined surface on the inside of the drum. This rubbing action reduces the rotation of the brake drum, which is coupled to the wheel. Hence the speed of the vehicle is reduced. When the pressure is released, return springs pull the shoes back to their rest position…