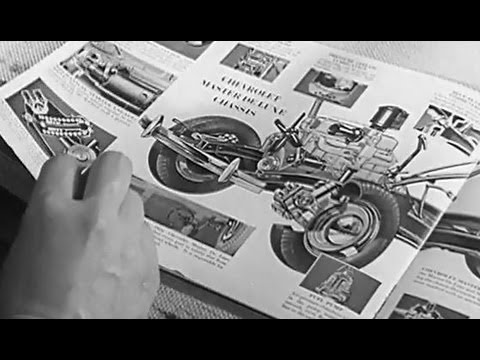

Engraved Printing: “Heights and Depths” 1938 Chevrolet Film on Rotogravure

more at

“Principles of engraving are dramatized, showing that the tones of pictures result from high and low places on the engraver’s plate.”

NEW VERSION with improved video & sound:

Public domain film from the Library of Congress Prelinger Archive, slightly cropped to remove uneven edges, with the aspect ratio corrected, and mild video noise reduction applied.

The soundtrack was also processed with volume normalization, noise reduction, clipping reduction, and/or equalization (the resulting sound, though not perfect, is far less noisy than the original).

Rotogravure (Roto or Gravure for short) is a type of intaglio printing process; that is, it involves engraving the image onto an image carrier. In gravure printing, the image is engraved onto a cylinder because, like offset printing and flexography, it uses a rotary printing press. Once a staple of newspaper photo features, the rotogravure process is still used for commercial printing of magazines, postcards, and corrugated (cardboard) product packaging…

History and development

In the last quarter of the 19th century, the method of image photo transfer onto carbon tissue covered with light-sensitive gelatin was discovered, and was the beginning of rotogravure. In the 1930s–1960s, newspapers published relatively few photographs and instead many newspapers published separate rotogravure sections in their Sunday editions. These sections were devoted to photographs and identifying captions, not news stories. Irving Berlin’s song “Easter Parade” specifically refers to these sections in the lines “the photographers will snap us, and you’ll find that you’re in the rotogravure”. And the song “Hooray for Hollywood” contains the line “…armed with photos from local rotos” referring to young actresses hoping to make it in the movie industry.

In 1932 a George Gallup “Survey of Reader Interest in Various Sections of Sunday Newspapers to Determine the Relative Value of Rotogravure as an Advertising Medium” found that these special rotogravures were the most widely read sections of the paper and that advertisements there were three times more likely to be seen by readers than in any other section.

Components

The first step of Gravure is to create the cylinder with the engraved images that need to be printed: the engraving process will create on the cylinder surface the cells that will contain the ink in order to transfer it to the paper. Since the amount of ink contained in the cells corresponds to different colour intensities on the paper, the dimensions of the cells must be carefully set: deeper cells will produce more intensive colours whereas less deep cells will produce less intensive ones. There are three methods of photoengraving that have been used for engraving of gravure cylinders, where the cell open size or the depth of cells can be uniform or variable…

Gravure cylinders are usually made of steel and plated with copper and a light-sensitive coating. Previously machined to remove imperfections in the copper, most cylinders are now laser engraved. In the past, they were either engraved using a diamond stylus or chemically etched using ferric chloride, which creates pollution. If the cylinder was chemically etched, a resist (in the form of a negative image) was transferred to the cylinder before etching. The resist protects the non-image areas of the cylinder from the etchant. After etching, the resist was stripped off. The operation is analogous to the manufacture of printed circuit boards. Following engraving, the cylinder is proofed and tested, reworked if necessary, and then chrome plated.

A rotogravure printing press has one printing unit for each color, typically CMYK or cyan, magenta, yellow and key (printing terminology for black), but the number of units varies depending on what colors are required to produce the final image. There are five basic components in each color unit: an engraved cylinder (AKA “Gravure cylinder”) whose circumference can differ according to the layout of the job; an ink fountain; a doctor blade; an impression roller; a dryer…

Because gravure is capable of transferring more ink to the paper than other printing processes, it is noted for its remarkable density range (light to shadow) and hence is a process of choice for fine art and photography reproduction, though not typically as clean an image as that of offset lithography. Gravure’s major quality shortcoming is that all images, including type and “solids,” are actually printed as dots, and the screen pattern of these dots is readily visible to the naked eye…